Transform Your Space with an Indoor Waterfall Waterwall: A 140kg Glass Slab Journey

Transform Your Space with an Indoor Waterfall Waterwall: A 140kg Glass Slab Journey

Creating a tranquil indoor waterfall waterwall can elevate your living space, bringing in serenity and elegance. In this post, we’ll take you through the exciting journey of moving and installing a hefty 140kg glass slab for an indoor waterfall. Whether you’re a DIY enthusiast, a craftsman, or just curious, there’s plenty to learn from our experiences, challenges, and triumphs. Let’s dive in!

Table of Contents

- 🌟 Intro

- 🚚 Loading the Glass Slab

- 🔧 Inserting the Glass Slab

- 🔄 Returning the GMG 350

- 🏁 Conclusion

- ❓ FAQ

🌟 Intro

Welcome to our adventure at the Wawazen Waterwall School! Today, we're sharing some heavy moments from our waterfall installation. Not only did we handle a 140kg glass slab, but we also navigated through numerous challenges that come with such a significant project. If you’ve ever worked with glass, you’ll appreciate the intricacies involved, and who knows, you might pick up some valuable insights along the way!

🚚 Loading the Glass Slab

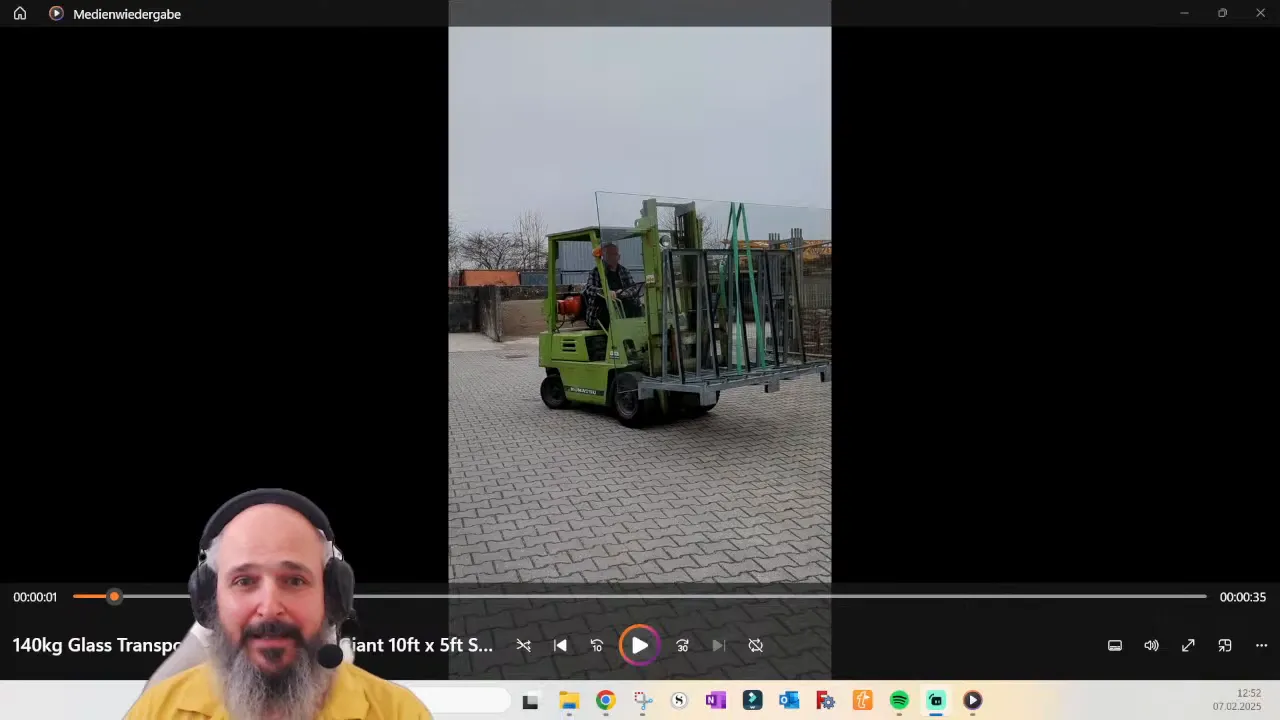

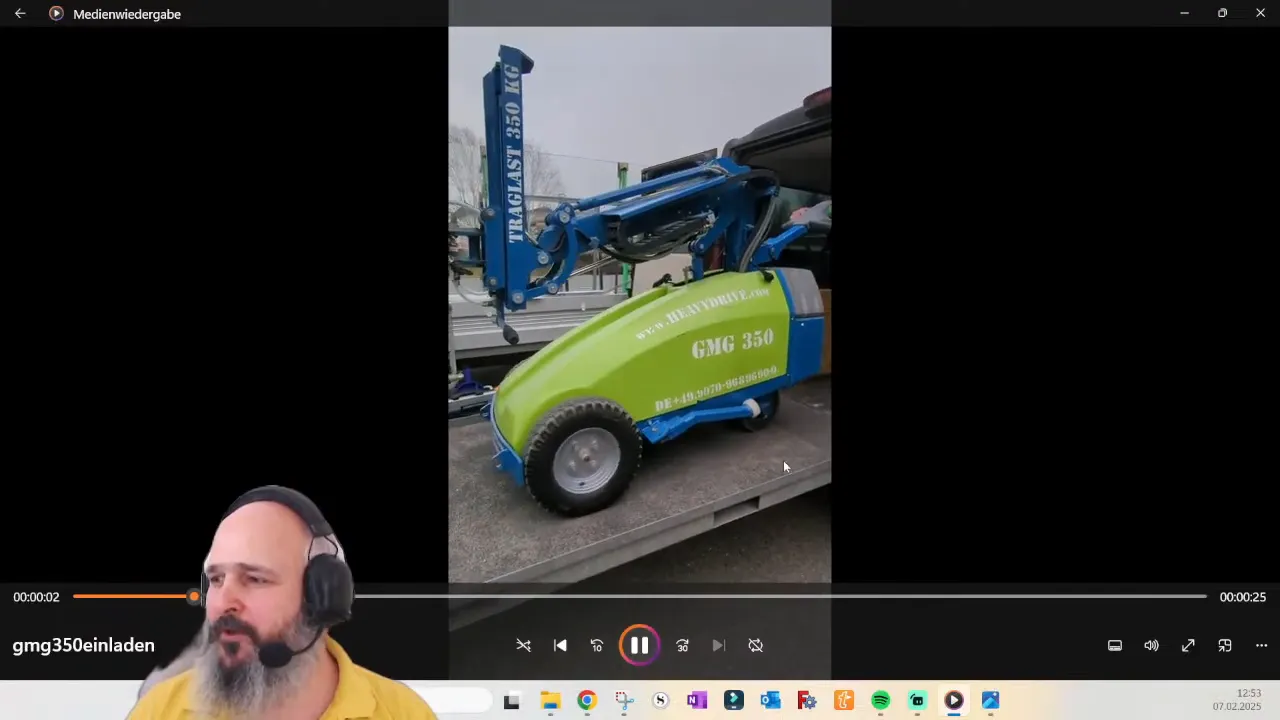

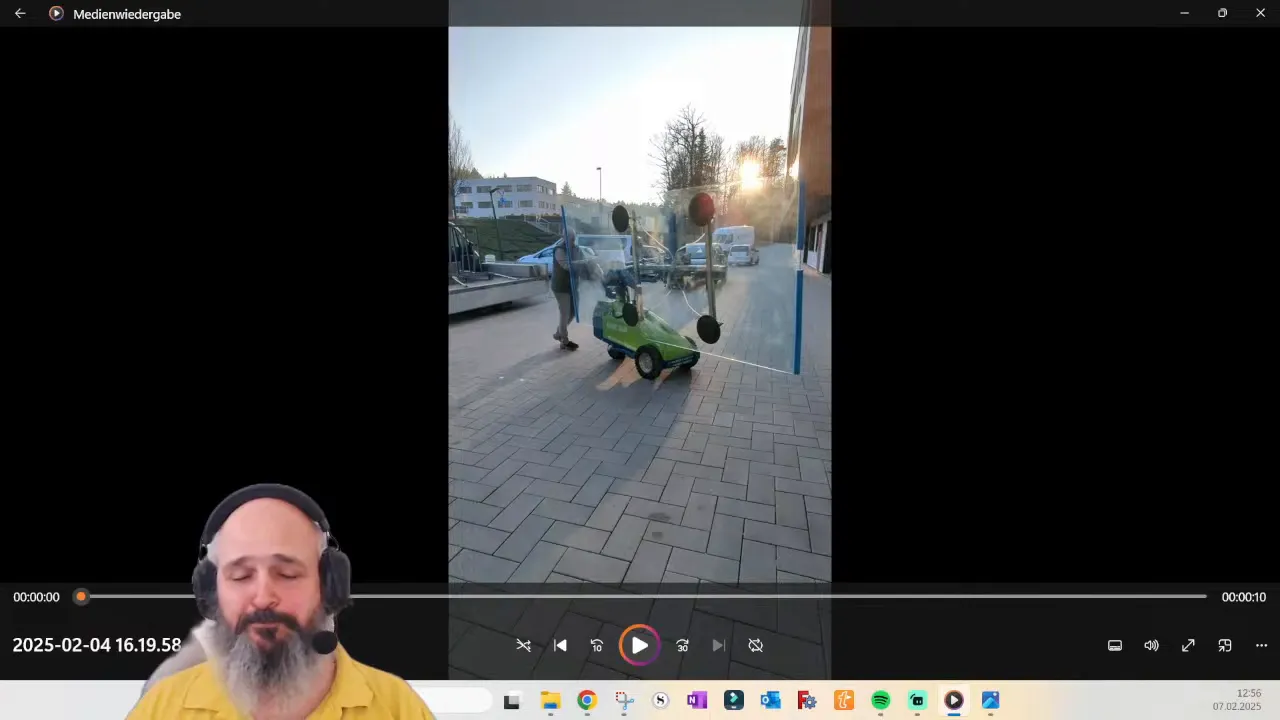

A few days ago, we began by loading the glass slab onto our trailer. Tommy skillfully maneuvered the massive ten-foot by five-foot slab, weighing in at 140 kilograms. We then headed to a reliable company called Heavy Drive, where we rented a GMG 350 glass mover. The team there is fantastic, and their equipment is top-notch!

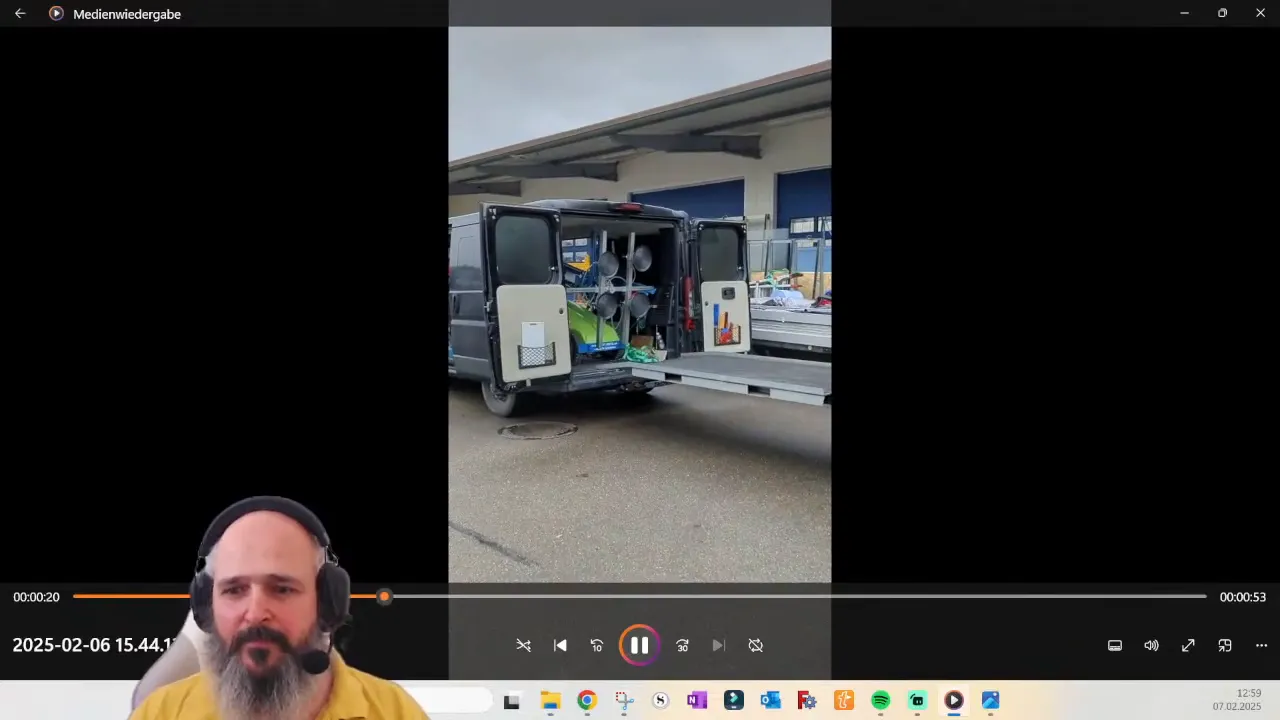

Once at Heavy Drive, we had the GMG 350 driven onto a platform, which was then moved by a forklift. The process was a bit tricky. The forklift operator had to squeeze the GMG into our transporter, navigating tight spaces. The wooden slabs on the sides made it nearly impossible for him to exit the transporter. It was quite a sight to see him maneuver through that gap!

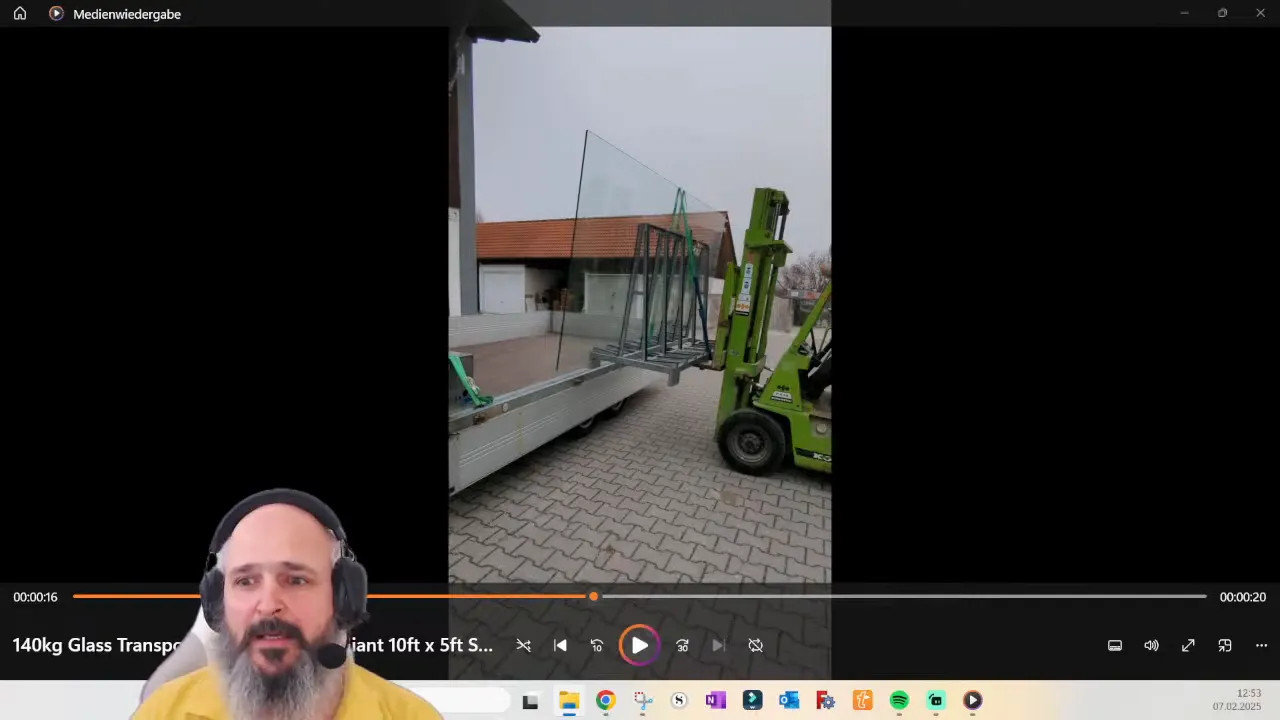

After successfully fitting the GMG 350 inside, we loaded all the necessary indoor waterfall equipment. This proved to be a challenge since the space was tight. Nonetheless, we managed to drive to our site, unload our tools, and prepare for the next steps.

🔧 Inserting the Glass Slab

Once we arrived at the installation site, it was time to drive the GMG 350 out of the transporter. Tommy was a bit frustrated with me for filming while he wrestled with the machine, but we got it out without any damage. The next challenge was to lift the glass slab from the trailer onto the GMG 350.

Fortunately, we had sunshine on our side, even though it was a chilly day. We placed the slab on the GMG, but soon encountered our first hurdle. We needed to get the slab through a standard door to enter the customer's space—a dentist's office. The door was narrow, and we had to ensure we didn’t damage the slab or the floor.

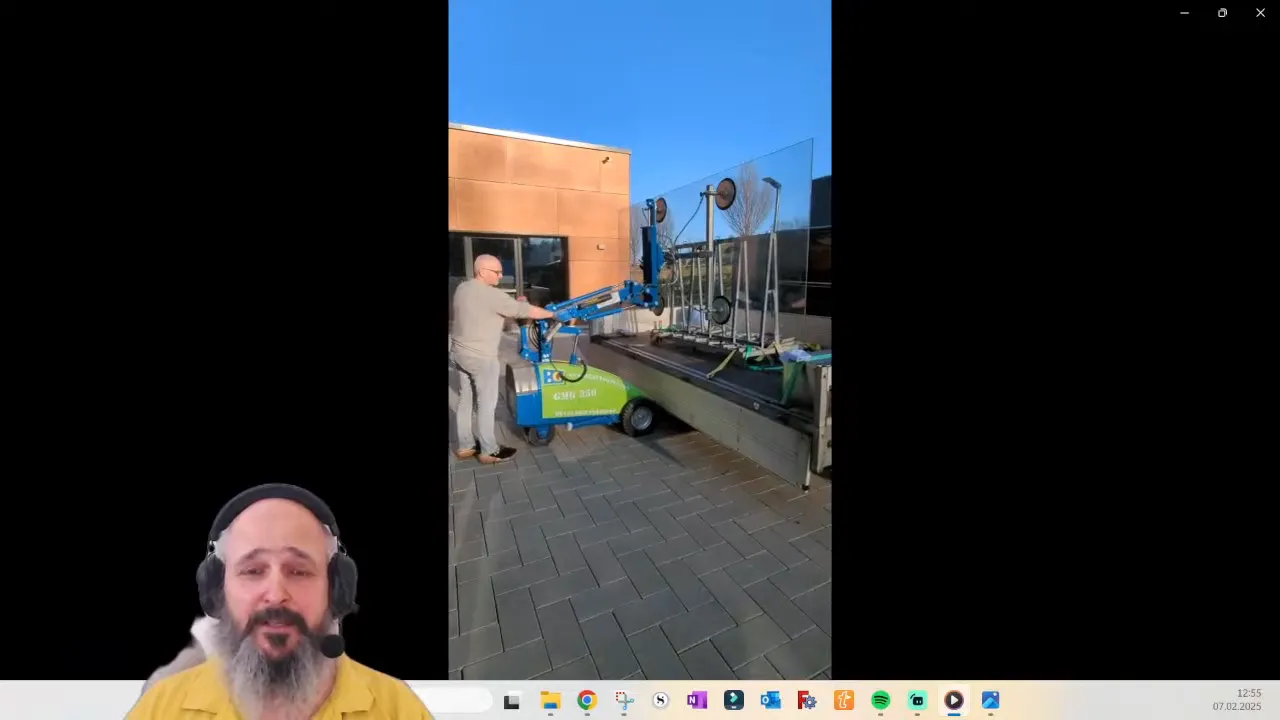

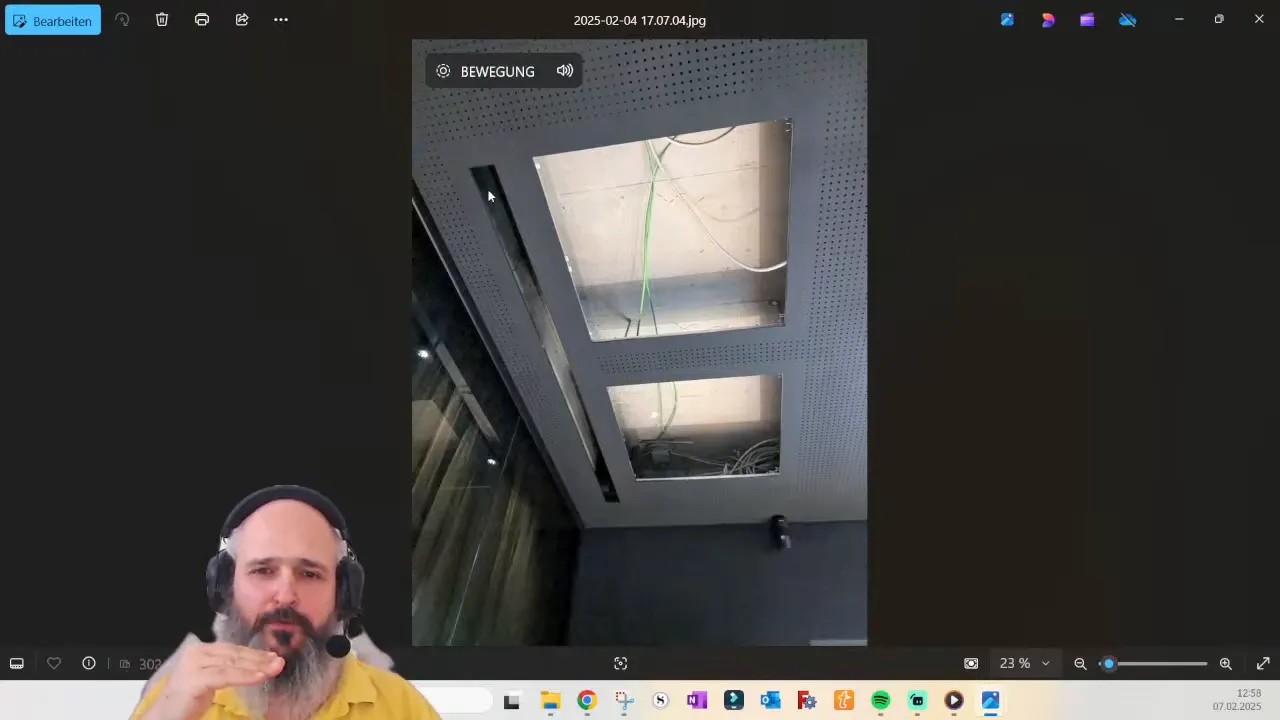

To protect the floor, we laid down wooden slabs, affectionately called bee slabs. As we maneuvered the slab and the GMG through the doorway, we faced another issue: the GMG couldn’t reach the floor properly. It was still about twenty centimeters short!

We had to lift the slab using our strength, but thankfully, the sucker plates helped support the glass's weight. However, the GMG was reluctant to lift it due to its heavy load. In a moment of teamwork, Tommy sat on the machine while I pushed from the other side, and finally, the GMG 350 was ready to lift the glass slab into position.

This process was quite thrilling! The GMG can only perform one movement at a time, so we had to coordinate carefully—two centimeters forward, one centimeter up, repeat. It was a slow but steady approach, and thankfully, we successfully placed the glass slab without a scratch.

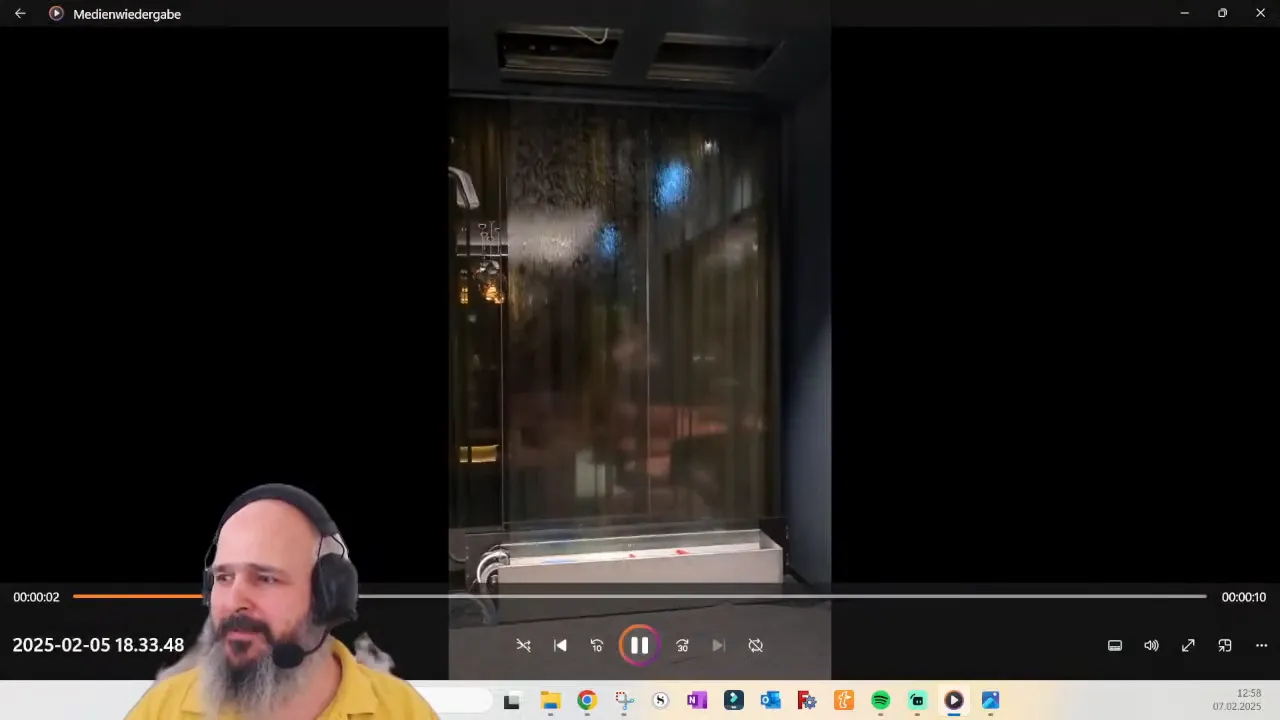

🔄 Returning the GMG 350

By the end of the day, we had successfully inserted the glass slab, and the indoor waterfall was running beautifully! It was a long, exhausting day, but everything went smoothly. Tommy had to drive the GMG back into the transporter, and as night fell, we were both feeling the fatigue of a job well done.

After packing up the GMG, we returned to Heavy Drive to return the equipment. It was gratifying to see the forklift once again assist in unloading the GMG 350 from our transporter. We felt accomplished and proud of what we had achieved together.

🏁 Conclusion

This installation was hard work, and while we relied heavily on the machine, there were moments we had to lift the slab by ourselves. It was a physically demanding project, but also incredibly rewarding. Tommy, who had experience with the GMG, drove it, while I documented the process.

Overall, we had a great time, despite the challenges. We learned a lot about teamwork, communication, and the importance of planning. If you’re considering starting your own indoor waterfall business or undertaking a DIY project, I’d love to help you with the planning process. Remember, every ten minutes spent in planning can save you an hour on-site!

Effective communication is key in any project. It's not just about us; we had to coordinate with the plumber, the architect, the carpenter, and the customer. The smoother the communication, the better the outcome. Thank you for joining us in this journey of creating an indoor waterfall waterwall!

❓ FAQ

What is an indoor waterfall waterwall?

An indoor waterfall waterwall is a decorative water feature that can be installed in homes or businesses, creating a soothing ambiance and aesthetic appeal through the sound and sight of flowing water.

How do you install an indoor waterfall waterwall?

Installation often involves planning the layout, transporting heavy glass slabs, using specialized equipment like the GMG 350, and ensuring proper communication among all parties involved in the project.

What are the benefits of having an indoor waterfall?

Indoor waterfalls can improve air quality, reduce stress, and enhance the overall atmosphere of a space by adding a calming water element.

Do I need special tools to create an indoor waterfall?

Yes, heavy lifting equipment, such as a glass mover, is often necessary for handling large glass slabs. Additionally, basic tools for installation will be required based on the specific design.

How can I maintain my indoor waterfall waterwall?

Regular cleaning and maintenance are essential. This includes using distilled water to prevent mineral buildup, treating algae growth, and ensuring the pump is functioning correctly.

Thank you for reading! If you have any questions or would like to share your thoughts, please leave a comment below. Let’s create something amazing together!

This article was created from the video How We Moved a 140kg Glass Slab for an Indoor Waterfall 🚚 with the help of AI.